手縫いとミシンの違い

ミシン縫製は下糸を上糸がすくい上げて縫う為、糸が切れると連続してほつれる可能性があります。しかし手縫いは糸を交差して縫う為、擦り切れても連続してほつれないという利点があります。馬具や靴等の擦り切れる可能性がある部分には、今だに手縫いが使われるのはこの為です。手間やコスト・技術が要る手縫いはアジがあるだけでなく、物理的に強い縫い方です。

淡路谷佳幸が縫い上げます

ミシン針が折れてしまうような非常に強い力が必要な為、指や手首の力は通常の職人の腕とは異なります。

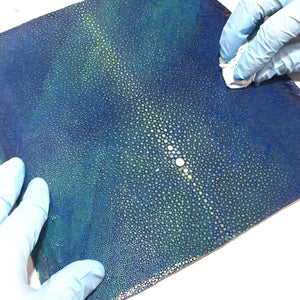

Only the finest stingray leather is used

There are various grades of stingray leather. Each stingray is hand-checked for any easily falling off scales, and only soft leather with uniform grains is used.

Beautifully polished pearls

By carefully polishing the leather over and over again, we create a leather that is smooth to the touch and has a unique, lustrous, beautiful shine.

The tension of the leather can be adjusted to suit the piece

The adhesive method is changed in detail, and the pieces are pressed and dried over a period of several days to several weeks to create a strong bond. By carefully bonding the pieces over a long period of time, the material can be adjusted to suit the characteristics of the work, from soft materials like cloth to hard and sturdy belts.

Strong edges made of multiple thin layers

The cut edges of stingray leather are hard and sharp, so this is an important and difficult process. By repeating the process of "painting → drying → hand polishing" more than five times, we can create a beautiful and durable edge.